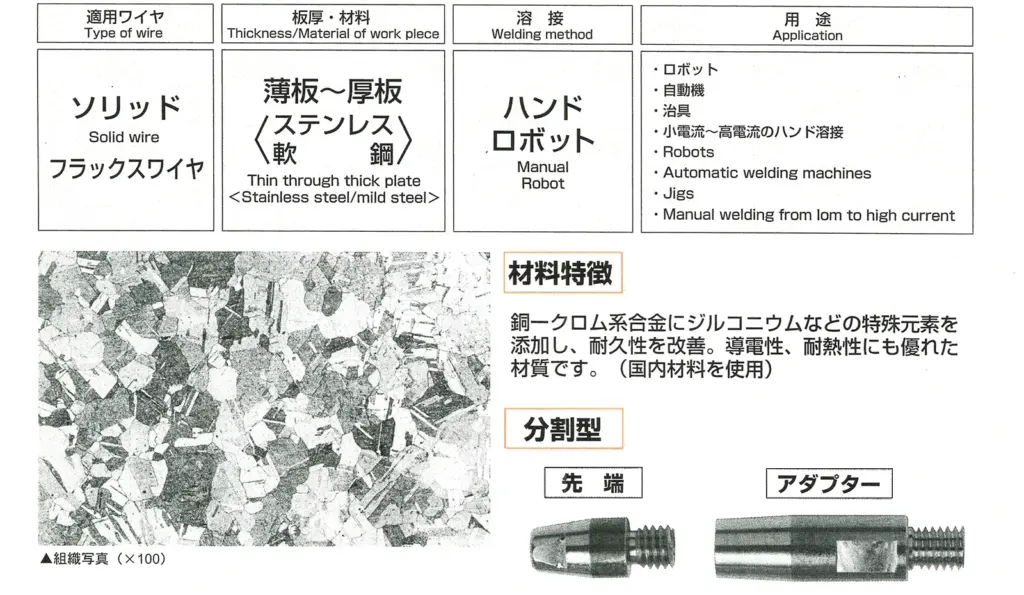

Split-type high-durability welding contact tip | Alpha Tip Split-type

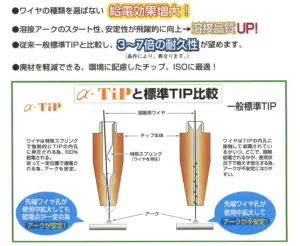

The welding wire is in contact with the inner hole of the contact tip to supply electricity, but because the contact point is constantly changing as the wire is supplied to the base material, the power required for welding tends to be unstable.

Furthermore, continuous use of standard contact tips can cause the wire hole at the tip to wear out, resulting in arc distortion.

In order to solve the many problems that existed with conventional contact tips, we developed our own original Alpha Tip, an improved version that makes it easier to handle: the split type Alpha Tip.

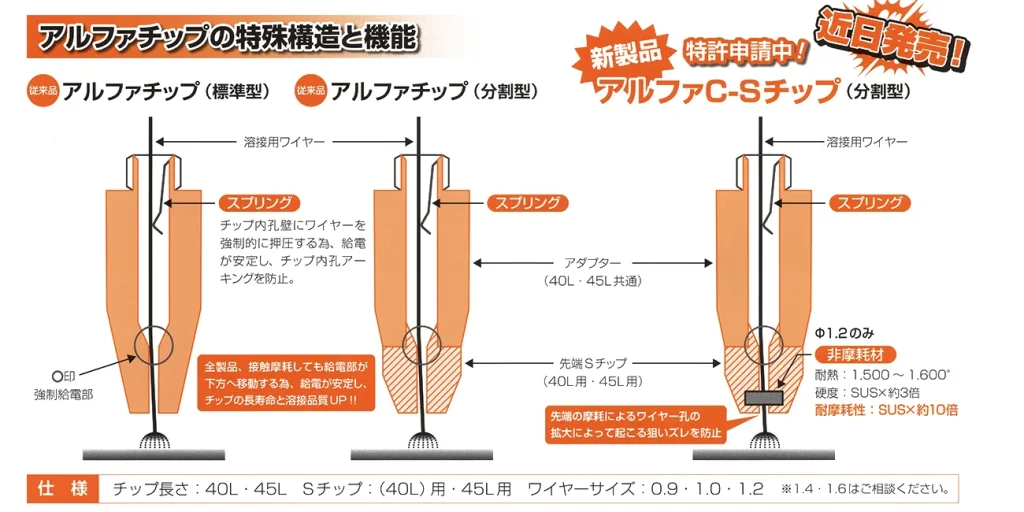

First, here are the benefits of using the Alpha Chip standard type.

A special spring built into the Alpha Tip presses the wire so that it is constantly fed along the inner hole to the base material, making it possible to generate a very stable arc while maintaining a constant power.

Even if the tip wire hole expands, the pressure of the special spring keeps the power supply point constant and minimizes vibration, resulting in 3 to 7 times greater durability than conventional standard tips.*1

By extending the replacement cycle for contact tips, waste material generation can be reduced, reducing consumable costs and achieving ISO14001 certification, and our proprietary Alpha Tip solves previously unattainable problems such as environmental friendliness.

Our Alpha Chip split type is an improvement on the popular standard Alpha Chip type.

The Alpha Tip Split Type has a split structure consisting of an adapter with a built-in special spring and the tip S-tip, which is prone to wear, making it possible to reduce costs even further than before.

Standard contact tips and our standard Alpha Tip have the disadvantage that the entire tip must be replaced when the tip becomes worn out. However, by making the part that is less prone to wear into an adapter and making only the tip S-tip, which is more prone to wear, a separate replaceable part, we are able to sell them as separate parts with different replacement cycles.

By miniaturizing the parts that need to be replaced or disposed of, we have reduced the cost of replacing consumables and added this eco-friendly contact tip to our lineup, which is also kind to the global environment.

Suitable wire diameters range from Φ0.9 to Φ1.4, and tip lengths of 40L and 45L are available.

| Product name | Alpha Tip (split type) |

| Compatible welding machines | |

| Suitable wire diameter | Φ0.9, Φ1.0, Φ1.2, Φ1.4 /Other diameters available upon request |

| Compatible wire materials | Solid & Flux |

| Tip length (adapter and tip S tip combined) | 40L・45L |

| retail price |

※1 使用条件により異なります。

Precautions for use

The α-Tip integrated and separate adapters have a special spring built in, so please check the following points.

- Adjust the pressure of the wire feeder to be slightly stronger.

- Use with torches 4m or less…Standard feed motor specifications

However, if a long torch feeder is used, it can also be used with 6m torches. - Please clean the coil liner, etc., as dirt may cause poor feeding.